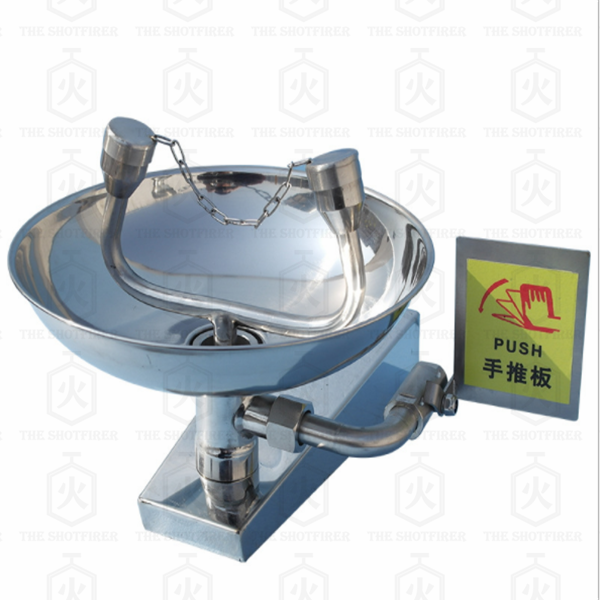

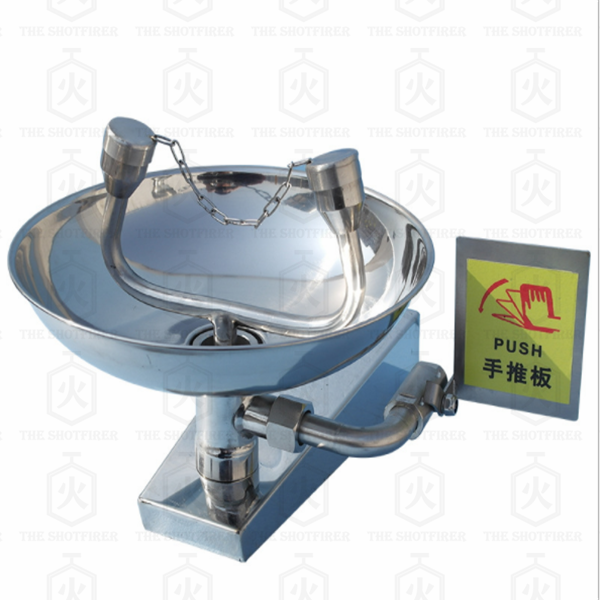

$ 120 Per Set

· 304 stainless steel composite emergency shower eyewash vertical shower set , Compound emergency double eye washer

· eyewash shower set

· 2 ways water inlet , as our pic shows The compound emergency eye washing device is widely used in the dangerous working areas and laboratories of pharmaceutical, chemical, petrochemical, electronic and semiconductor enterprises. When a chemical liquid or toxic substance splashes on the body, face, eyes of the staff or a fire causes the clothing of the staff to catch fire, the device can quickly reduce the harm to the lowest level and reduce the harm of the toxic substance to the staff Performance parameters: Nominal pressure: 0.4MPa Sealing pressure: 0.45MPa Working pressure: 0.20 ~ 0.40MPa Spray flow L / min: 120-180 Eyewash flow L / min: ≥ 12 Applicable conditions: pure water at room temperature or water meeting the sanitary standard Structural features: 1. Use ball valve to control spray and eye wash respectively. Convenient operation, fast opening and closing, reliable sealing. 2. the outlet of the sprinkler nozzle is a soft foaming water flow, which improves the cleaning efficiency by 50% compared with the common eye washing nozzle. 3. It is super resistant to the corrosion of acid, alkali, salt, oil and other chemicals. Installation and commissioning: 1. The product model, certificate, instruction manual and packing list shall be rechecked before installation. 2. The installation position shall be within 15 meters from the accident prone place, and the flushing place can be reached within 10 seconds at the running speed. 3. Installation and commissioning: A. connection between the base and the lower part of the riser: screw the raw material belt around the base thread to connect with the water outlet tee. B. installation of base: adjust the direction of tee drainage outlet according to the position of drainage pipe, mark the drilling position according to the screw hole of base, and then set M10 expansion screw or anchor bolt according to the ground level. C. install the flushing pipeline: screw the flushing nozzle on the elbow of the horizontal pipe of the nozzle, wrap the raw material belt around the other end of the nozzle pipe, screw it on the upper half of the riser, adjust the direction to make the direction of the flushing nozzle downward, and then lock the nozzle pipe with the back nut; D. connect the upper half and the lower half: place the upper half and the lower half into the upper half and tighten the upper half. E. install the eyewash basin: wrap the raw material belt around the thread of the lower part of the eyewash basin, and connect and tighten it with the reducing tee of the lower part. F. installation of double nozzle eyewash part: put g ? "mesh pad into G ?" lock nut and connect with G ? "connecting pipe Tighten. G. connect the water inlet pipe and drain pipe, and check whether the ball valve switch is flexible and in place, and whether there is jamming. H. the middle of the two pipes of the eye wash double nozzle is the eye wash flow regulating valve, and the flow of the eye wash nozzle is controlled by the flow regulating valve. The factory has been debugged. However, due to the difference of water supply pressure and flow, it can be readjusted on site during installation to the appropriate flow for human eyes. Adjustment method: screw off the top protective cap, use a slotted screwdriver to adjust the valve rod, rotate clockwise, and reduce the flow. Rotate counter clockwise to increase the flow. Tips: 1. The product is used in the environment above 0 ℃, if it is used below 0 ℃, the pipeline antifreeze maintenance is required; 2. Before installation, please flush the water inlet pipe in advance; 3. It is recommended to install the water inlet control valve in the water inlet pipeline. After use, close the water inlet control valve first, and then close the eye wash valve after the water in the main body is drained usage method: Open the water inlet control valve before use 1. When flushing is needed, please pull down the handle of flushing switch, open the flushing valve (opening angle 90 °), push up the handle of flushing switch, and close the flushing valve. (the ball valve connecting rod is closed 45 ° above the ball valve and open 45 ° below) 2. If eye wash is needed, please push the push plate of eye wash switch clockwise, open the eye wash valve, pull back the push plate anticlockwise, and close the eye wash valve. Maintenance: 1. It is only allowed to use in case of accident. It is strictly prohibited to use it for bathing at ordinary times. Rules and regulations and patrol inspection shall be stipulated to prevent illegal use or use it as regular bathing and hand washing appliances, resulting in product failure and resulting in unexpected accidents. 2. More than one comprehensive test shall be carried out every week to test the reliability and effectiveness of the device, so as to ensure the emergency and effective use in case of accident and reliably provide personal safety and health protection. This product is not medical equipment, only for emergency shower and reduce the harm of harmful substances to human body. 3. In the event of an accident, the victim shall choose the flushing time according to the degree of damage caused by harmful substances. Prepare emergency rescue measures during the period. Optional configuration: pedal, ABS coating and lighting device can be added, anti freezing device can be added, customized according to customer requirements.

DETONATOR SAFETY BOX SEISMIC PORTABLE$ 23 +

DETONATOR SAFETY BOX SEISMIC PORTABLE$ 23 + MOVABLE MAGAZINE ASEMBLABLE $ 4500 +

MOVABLE MAGAZINE ASEMBLABLE $ 4500 + STATIC ELIMINATION/ALARM COLUMN$ 45 per Pc

STATIC ELIMINATION/ALARM COLUMN$ 45 per Pc EYESWASHIER EMERGENCY SHOWER SET$ 120 Per Set

EYESWASHIER EMERGENCY SHOWER SET$ 120 Per Set SIGNBOARD STICKER WARNING WATERPROOF$1.5 per Pc

SIGNBOARD STICKER WARNING WATERPROOF$1.5 per Pc DETONATOR PILLAR CARABLE$ 300 Per Set

DETONATOR PILLAR CARABLE$ 300 Per Set DETONATOR EXPLOSIVE SAFETY BOX SEISMIC$45 /PC

DETONATOR EXPLOSIVE SAFETY BOX SEISMIC$45 /PC EXLOSIVE MAGAZINE SMALL SIZE$180 /Set

EXLOSIVE MAGAZINE SMALL SIZE$180 /Set HARD BOX ON GROUND$450 /PC

HARD BOX ON GROUND$450 /PC EXPLOSIVE SAFETY TRUNKER FOR PIKUP$ 2200 /Set

EXPLOSIVE SAFETY TRUNKER FOR PIKUP$ 2200 /Set DETONATOR SAFETY BOX SEISMIC PORTABLE$ 23 +

DETONATOR SAFETY BOX SEISMIC PORTABLE$ 23 + MOVABLE MAGAZINE ASEMBLABLE $ 4500 +

MOVABLE MAGAZINE ASEMBLABLE $ 4500 + STATIC ELIMINATION/ALARM COLUMN$ 45 per Pc

STATIC ELIMINATION/ALARM COLUMN$ 45 per Pc EYESWASHIER EMERGENCY SHOWER SET$ 120 Per Set

EYESWASHIER EMERGENCY SHOWER SET$ 120 Per Set SIGNBOARD STICKER WARNING WATERPROOF$1.5 per Pc

SIGNBOARD STICKER WARNING WATERPROOF$1.5 per Pc DETONATOR PILLAR CARABLE$ 300 Per Set

DETONATOR PILLAR CARABLE$ 300 Per Set DETONATOR EXPLOSIVE SAFETY BOX SEISMIC$45 /PC

DETONATOR EXPLOSIVE SAFETY BOX SEISMIC$45 /PC EXLOSIVE MAGAZINE SMALL SIZE$180 /Set

EXLOSIVE MAGAZINE SMALL SIZE$180 /Set HARD BOX ON GROUND$450 /PC

HARD BOX ON GROUND$450 /PC EXPLOSIVE SAFETY TRUNKER FOR PIKUP$ 2200 /Set

EXPLOSIVE SAFETY TRUNKER FOR PIKUP$ 2200 /Set DETONATOR SAFETY BOX SEISMIC PORTABLE$ 23 +

DETONATOR SAFETY BOX SEISMIC PORTABLE$ 23 + MOVABLE MAGAZINE ASEMBLABLE $ 4500 +

MOVABLE MAGAZINE ASEMBLABLE $ 4500 + STATIC ELIMINATION/ALARM COLUMN$ 45 per Pc

STATIC ELIMINATION/ALARM COLUMN$ 45 per Pc EYESWASHIER EMERGENCY SHOWER SET$ 120 Per Set

EYESWASHIER EMERGENCY SHOWER SET$ 120 Per Set SIGNBOARD STICKER WARNING WATERPROOF$1.5 per Pc

SIGNBOARD STICKER WARNING WATERPROOF$1.5 per Pc DETONATOR PILLAR CARABLE$ 300 Per Set

DETONATOR PILLAR CARABLE$ 300 Per Set DETONATOR EXPLOSIVE SAFETY BOX SEISMIC$45 /PC

DETONATOR EXPLOSIVE SAFETY BOX SEISMIC$45 /PC EXLOSIVE MAGAZINE SMALL SIZE$180 /Set

EXLOSIVE MAGAZINE SMALL SIZE$180 /Set HARD BOX ON GROUND$450 /PC

HARD BOX ON GROUND$450 /PC EXPLOSIVE SAFETY TRUNKER FOR PIKUP$ 2200 /Set

EXPLOSIVE SAFETY TRUNKER FOR PIKUP$ 2200 /Set