$ 15000 +

Contact us to get further info: nasaengineer@qq.com rfq@theshotfirer.com

Whatsapp/Wechat:+8618055795537

Supported by:

www.kejali.biz info@kejali.biz Kejali Shenzhen

CO2 BLASTING SPLITTER

Pure mechanical, no explosive license would be required

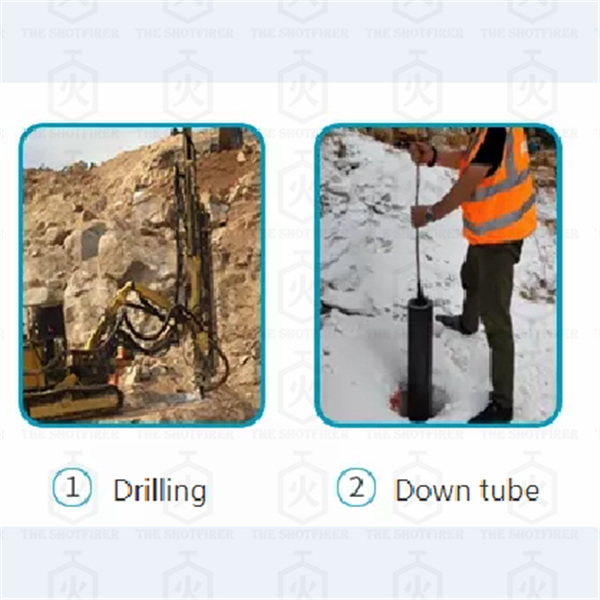

Gas expansion fracturing equipment (carbon dioxide cracking equipment) is to quickly convert liquid carbon dioxide (CO2) into gas after instantaneous heating. After gasification, the volume of carbon dioxide gas can increase dramatically by 600 times, causing objects or rock to be cracked The geometric equivalent impact breaks forward rapidly, from initiation to the entire process in only 0.4 seconds, and it runs at low temperature, and does not want to merge with the liquid and gas in the surrounding environment. Gas expansion fracturing equipment is usually used for the splitting of stone or concrete blocks for mining or demolition rescue, so it is also called carbon dioxide rock cracking equipment or carbon dioxide fracturing device. The process is actually the process of gas volume expansion, not to mention Shock wave, no vibration wave, no explosion shockwave, blasting effect of explosive but no safety hazard.

1. It has essential safety features. It is very safe in terms of storage, transportation, carrying, use, and recycling. The main engine is separated from the blasting equipment, and the time from filling to the end of blasting is short. The liquid carbon dioxide infusion only takes 1-3 minutes, and the detonation takes only 4 milliseconds. There is no dumb shot during the implementation process, and no inspection is required. The safety warning distance is short and there is no safety hazard. The blasting cylinder is easy to recycle and can be used continuously.

2. It can be directional blasting and time-delay control, especially in special environments, such as residential areas, tunnels, subways, underground and other environments. There is no destructive vibration and short wave during the implementation process, and no destructive impact on the surrounding environment.

3. The texture structure is not destroyed in the stone mining, and the yield and efficiency are high.

4. No pyrotechnic warehouse is needed, management is simple, operation is easy to learn, there are few operators, and no professional personnel are required to be on duty.

5. Its performance is more prominent when used in underground mines. It can be used in high gas mines, rock burst mines, mines with complex hydrogeological conditions, or mines that are prone to spontaneous combustion.

6. There are abundant sources of materials, and materials can be obtained locally. Improve efficiency, increase efficiency, and reduce costs. Reduce complicated approval procedures and management restrictions. All products are non-explosive before injecting carbon dioxide.

7. In order to obtain a larger equivalent power, the blasting cylinders can be used in parallel according to the site conditions.

8. In emergency rescue and rescue, all facilities can be consigned to any vehicle. The detonator explosive is a controlled item without this advantage. Can save a lot of rescue time.

Model | Borehole(mm) | CO2Charge(kg) | Length(m) |

36 | 40 | 1 | 1.2 |

52 | <65 | 1 | 0.7 |

2 | 1.2 | ||

76 | 90 | 2 | 0.7 |

3 | 1 | ||

5 | 1.6 | ||

98 | 115 | 2 | 0.4 |

3 | 0.7 | ||

5 | 1 |

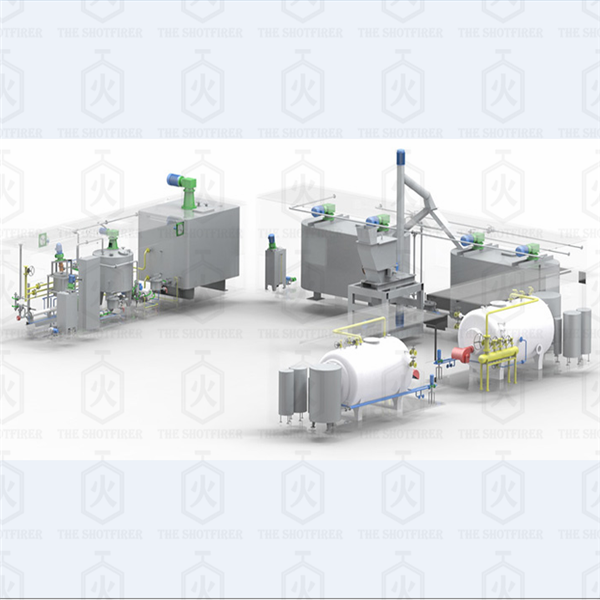

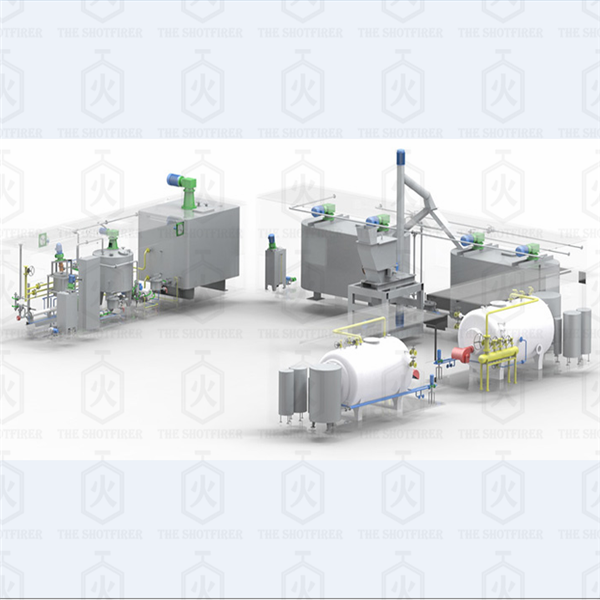

EMULSION MSU MOBILE SENSITIZING UNIT$ 220000

EMULSION MSU MOBILE SENSITIZING UNIT$ 220000 EMULSION PLANT ASEMBLABLE MOVABLE$ 750000

EMULSION PLANT ASEMBLABLE MOVABLE$ 750000 PNEUMATIC DRUM PUMP CHEMICAL AIRCOMPRESSOR$ 520 Per Set

PNEUMATIC DRUM PUMP CHEMICAL AIRCOMPRESSOR$ 520 Per Set CO2 BLASTING SPLITTER NO BLAST LICENSE$ 15000 +

CO2 BLASTING SPLITTER NO BLAST LICENSE$ 15000 + HYDRALIC SPLITTER MANUAL $ 800 Per Set

HYDRALIC SPLITTER MANUAL $ 800 Per Set Piston Rock Splitter6000USD

Piston Rock Splitter6000USD AIR PICK BREAKER PNEUMATIC$70 /PC

AIR PICK BREAKER PNEUMATIC$70 /PC ANFO MSU MIXER AUGER$ 120000

ANFO MSU MIXER AUGER$ 120000 CHARGER PUMP UG UPHOLES$ 120000

CHARGER PUMP UG UPHOLES$ 120000 NAPCO PUMP$520 /Set

NAPCO PUMP$520 /Set EMULSION MSU MOBILE SENSITIZING UNIT$ 220000

EMULSION MSU MOBILE SENSITIZING UNIT$ 220000 EMULSION PLANT ASEMBLABLE MOVABLE$ 750000

EMULSION PLANT ASEMBLABLE MOVABLE$ 750000 PNEUMATIC DRUM PUMP CHEMICAL AIRCOMPRESSOR$ 520 Per Set

PNEUMATIC DRUM PUMP CHEMICAL AIRCOMPRESSOR$ 520 Per Set CO2 BLASTING SPLITTER NO BLAST LICENSE$ 15000 +

CO2 BLASTING SPLITTER NO BLAST LICENSE$ 15000 + HYDRALIC SPLITTER MANUAL $ 800 Per Set

HYDRALIC SPLITTER MANUAL $ 800 Per Set Piston Rock Splitter6000USD

Piston Rock Splitter6000USD AIR PICK BREAKER PNEUMATIC$70 /PC

AIR PICK BREAKER PNEUMATIC$70 /PC ANFO MSU MIXER AUGER$ 120000

ANFO MSU MIXER AUGER$ 120000 CHARGER PUMP UG UPHOLES$ 120000

CHARGER PUMP UG UPHOLES$ 120000 NAPCO PUMP$520 /Set

NAPCO PUMP$520 /Set EMULSION MSU MOBILE SENSITIZING UNIT$ 220000

EMULSION MSU MOBILE SENSITIZING UNIT$ 220000 EMULSION PLANT ASEMBLABLE MOVABLE$ 750000

EMULSION PLANT ASEMBLABLE MOVABLE$ 750000 PNEUMATIC DRUM PUMP CHEMICAL AIRCOMPRESSOR$ 520 Per Set

PNEUMATIC DRUM PUMP CHEMICAL AIRCOMPRESSOR$ 520 Per Set CO2 BLASTING SPLITTER NO BLAST LICENSE$ 15000 +

CO2 BLASTING SPLITTER NO BLAST LICENSE$ 15000 + HYDRALIC SPLITTER MANUAL $ 800 Per Set

HYDRALIC SPLITTER MANUAL $ 800 Per Set Piston Rock Splitter6000USD

Piston Rock Splitter6000USD AIR PICK BREAKER PNEUMATIC$70 /PC

AIR PICK BREAKER PNEUMATIC$70 /PC ANFO MSU MIXER AUGER$ 120000

ANFO MSU MIXER AUGER$ 120000 CHARGER PUMP UG UPHOLES$ 120000

CHARGER PUMP UG UPHOLES$ 120000 NAPCO PUMP$520 /Set

NAPCO PUMP$520 /Set