$ 45

SAFETY FUSE COPPER - CRIMPING PLIER -TIE-UP&TESTER

5.4-6mm

This simple brass pliers-type crimping tool is used to crimp safety fuse end inside the mouth of plain detonators. The material brass which is a non-sparking metal is used for added safety. One of the legs of the tool is pointed, to puncture the explosive cartridge and the other is wide and flat to widen the hole in the cartridge and insert the cap inside the cartridge.

Explosion-proof tools are divided into two materials, aluminum copper alloy and beryllium copper alloy (also known as aluminum bronze and beryllium bronze). Aluminum-copper alloy explosion-proof tools are made of precious metals, smelted, and forged, and the surface is yellow. The hardness of the working face is above 25 degrees HRC, the tensile strength δ b> 75-85kgf/mm2, and all other technical indicators have reached the advanced level of similar foreign products. Continuous use in the space of flammable gas ethylene (concentration 7.8%) ensures safety, and no sparks and explosions are produced by impact (impact), friction, and drop hammer.

The beryllium copper alloy explosion-proof tool is a combination of special materials and precious and rare metals, and the surface of the tool is also yellow. The working surface hardness is above 35 degrees HRC, the tensile strength δ b>105-120kgf/mm2, and all other technical indicators have reached the advanced level of similar foreign products. The continuous use in the flammable gas hydrogen (concentration 21%) space can ensure safety and impact ( Impact, friction, and drop hammer will not produce sparks and explosions. Beryllium copper alloy explosion-proof tools also have a special anti-magnetic function, which can be used normally in a working environment with a magnetic field.

Product features: It can effectively prevent the tool from rubbing against the work object. There will be no sparks or explosions in the impact. It can avoid personal injury and property loss. It is a safe explosion-proof tool.

LEAD WIRE TAKE UP ROLL ARMY USE BLACK$ 0.05 Per M

LEAD WIRE TAKE UP ROLL ARMY USE BLACK$ 0.05 Per M CONNECTION WIRE COPPER 0.5MM 0.6MM$ 0.05 Per M

CONNECTION WIRE COPPER 0.5MM 0.6MM$ 0.05 Per M OHMMETER ELECTIC BLAST TESTER CHB-2000$ 100 Per Pc

OHMMETER ELECTIC BLAST TESTER CHB-2000$ 100 Per Pc MULTITOOL PLIER CUTTER KNIFE$ 20 /PC

MULTITOOL PLIER CUTTER KNIFE$ 20 /PC CABLE STRIPPER/CUTTER SHOCKTUBE$ 1.5 Per Pc

CABLE STRIPPER/CUTTER SHOCKTUBE$ 1.5 Per Pc CRIMPING PLIER SAFETY FUSE COPPER$ 45

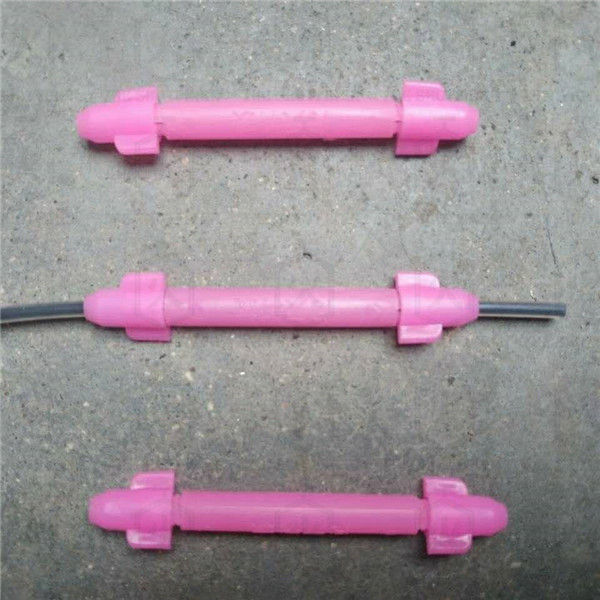

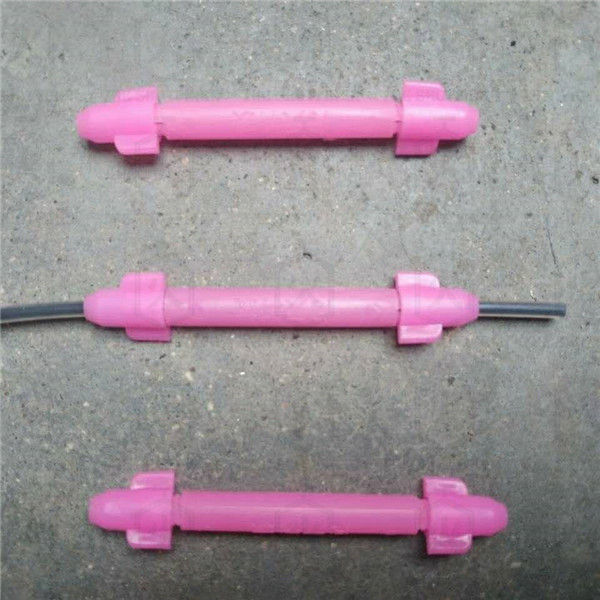

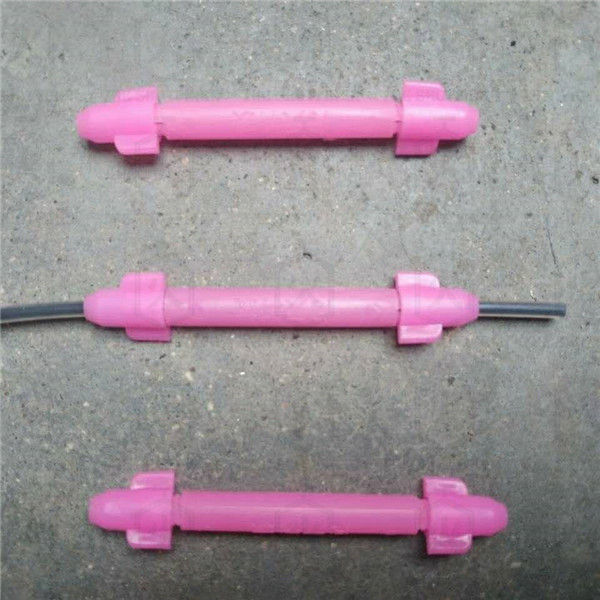

CRIMPING PLIER SAFETY FUSE COPPER$ 45 NONEL CONNECTOR MULPIICATOR PLASTIC$0.02 per Pc

NONEL CONNECTOR MULPIICATOR PLASTIC$0.02 per Pc DETONATOR TESTER 2H-6 MULTIMETER$60 per Unit

DETONATOR TESTER 2H-6 MULTIMETER$60 per Unit GALVANIZED BLASTING WIRE LEAD WIRE CONNECTION$ 0.05

GALVANIZED BLASTING WIRE LEAD WIRE CONNECTION$ 0.05 BLASTING WIRE STANDARD POLYVINYL CHLORIDE$0.05 /Meter

BLASTING WIRE STANDARD POLYVINYL CHLORIDE$0.05 /Meter LEAD WIRE TAKE UP ROLL ARMY USE BLACK$ 0.05 Per M

LEAD WIRE TAKE UP ROLL ARMY USE BLACK$ 0.05 Per M CONNECTION WIRE COPPER 0.5MM 0.6MM$ 0.05 Per M

CONNECTION WIRE COPPER 0.5MM 0.6MM$ 0.05 Per M OHMMETER ELECTIC BLAST TESTER CHB-2000$ 100 Per Pc

OHMMETER ELECTIC BLAST TESTER CHB-2000$ 100 Per Pc MULTITOOL PLIER CUTTER KNIFE$ 20 /PC

MULTITOOL PLIER CUTTER KNIFE$ 20 /PC CABLE STRIPPER/CUTTER SHOCKTUBE$ 1.5 Per Pc

CABLE STRIPPER/CUTTER SHOCKTUBE$ 1.5 Per Pc CRIMPING PLIER SAFETY FUSE COPPER$ 45

CRIMPING PLIER SAFETY FUSE COPPER$ 45 NONEL CONNECTOR MULPIICATOR PLASTIC$0.02 per Pc

NONEL CONNECTOR MULPIICATOR PLASTIC$0.02 per Pc DETONATOR TESTER 2H-6 MULTIMETER$60 per Unit

DETONATOR TESTER 2H-6 MULTIMETER$60 per Unit GALVANIZED BLASTING WIRE LEAD WIRE CONNECTION$ 0.05

GALVANIZED BLASTING WIRE LEAD WIRE CONNECTION$ 0.05 BLASTING WIRE STANDARD POLYVINYL CHLORIDE$0.05 /Meter

BLASTING WIRE STANDARD POLYVINYL CHLORIDE$0.05 /Meter LEAD WIRE TAKE UP ROLL ARMY USE BLACK$ 0.05 Per M

LEAD WIRE TAKE UP ROLL ARMY USE BLACK$ 0.05 Per M CONNECTION WIRE COPPER 0.5MM 0.6MM$ 0.05 Per M

CONNECTION WIRE COPPER 0.5MM 0.6MM$ 0.05 Per M OHMMETER ELECTIC BLAST TESTER CHB-2000$ 100 Per Pc

OHMMETER ELECTIC BLAST TESTER CHB-2000$ 100 Per Pc MULTITOOL PLIER CUTTER KNIFE$ 20 /PC

MULTITOOL PLIER CUTTER KNIFE$ 20 /PC CABLE STRIPPER/CUTTER SHOCKTUBE$ 1.5 Per Pc

CABLE STRIPPER/CUTTER SHOCKTUBE$ 1.5 Per Pc CRIMPING PLIER SAFETY FUSE COPPER$ 45

CRIMPING PLIER SAFETY FUSE COPPER$ 45 NONEL CONNECTOR MULPIICATOR PLASTIC$0.02 per Pc

NONEL CONNECTOR MULPIICATOR PLASTIC$0.02 per Pc DETONATOR TESTER 2H-6 MULTIMETER$60 per Unit

DETONATOR TESTER 2H-6 MULTIMETER$60 per Unit GALVANIZED BLASTING WIRE LEAD WIRE CONNECTION$ 0.05

GALVANIZED BLASTING WIRE LEAD WIRE CONNECTION$ 0.05 BLASTING WIRE STANDARD POLYVINYL CHLORIDE$0.05 /Meter

BLASTING WIRE STANDARD POLYVINYL CHLORIDE$0.05 /Meter